|

| TRADE

NAME |

| KANSAI

ELECTRIC HEAT CORP |

|

|

|

|

| CEO |

Mr.

Sadayoshi Taketsuna |

MainOffice

|

4-18, Takaida Nishi, 5-chome, Higashiosaka city,

Osaka 577-0067 Japan

Phone (06)6785-6001(Sales dep.)

FAX (06)6785-6002

E-MAIL sales@kansaidennetsu.co.jp

|

Tokyo

Branch |

4-4, Minami Kamata 2 chome, Oota ward, Tokyo 144-0035, Japan

Phone (03)5710-2001(Sales dep.) FAX (03)5710-2005

E-MAIL sales.tokyo@kansaidennetsu.co.jp |

2nd

Factory |

4-11, Takaida Nishi, 5-chome, Higashiosaka city, Osaka 577-0067 Japan |

| Holiday |

◆Calendar (working

hours: 8:40〜17:10) |

Overseas

Agencies |

DA CEI TRADE CO., LTD. (TAIWAN & CHINA)

13F, No.75, SEC 1, Hsin Tai Wu Rd., Hsichih, Taipei, Taiwan, R.O.C.

TEL

(02)8698-1111 FAX (02)8698-1000

E-MAIL sales@da-cei.com

HOMEPAGE http://www.da-cei.com

HANSHIN TECH CO., LTD. (KOREA)

#513, Mecajon EZEN APT Factory, Yangchon Industial Complex, Hakun-ri,

Yangchon-Myeon,

Gimpo-si, Kyeonggi-do, Korea

TEL (031)983-5424 FAX (031)983-5447

E-MAIL hanshinleem@naver.com

HOMEPAGE www.hanshintech.net

|

|

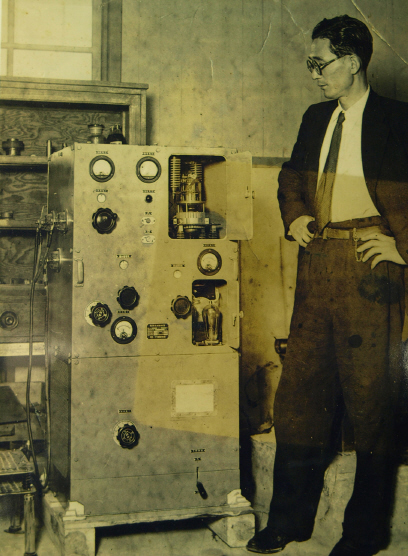

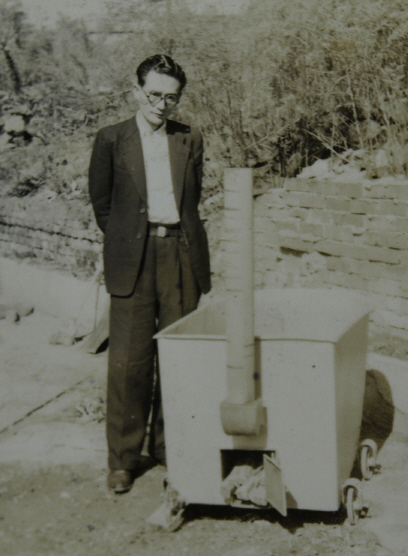

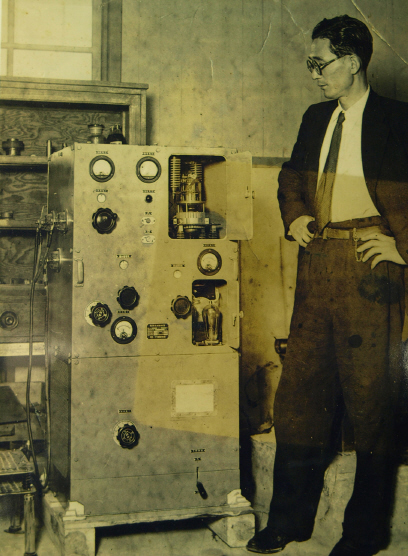

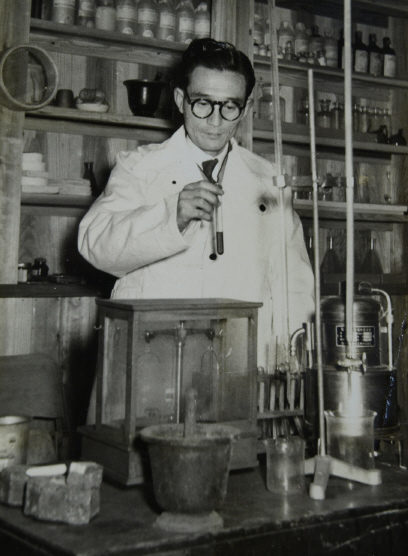

1931 Manufacture and sale of

physics and chemistry equipment.

90th anniversary of founding (2021). |

From

founding to prewar

Postwar products |

|

|

|

|

|

|

1939〜1950

Manufacture and sale of electric furnaces, high voltage generators,

and medical and chemical equipment at the Kyoto Factory |

1941〜1945

Harmonics as a cooperating factory of the Navy Electric Industry

Association

Manufacture of induction furnaces, etc. |

1945

The Osaka area was also scorched. Manufacture and sale of "buro

kettle", a daily necessities, using waste materials |

1946

Manufacture and sale of the first product hand dryer in Japan |

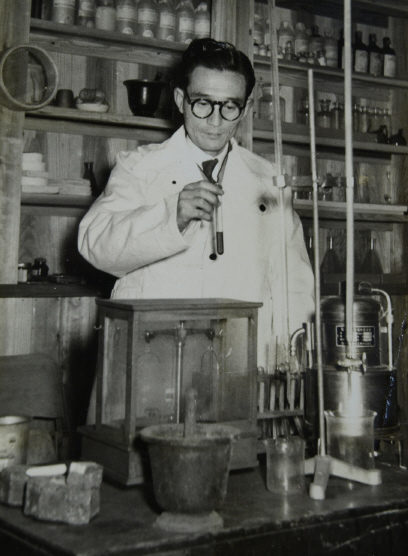

1945〜1952

Established Metal

Analysis Association (Industrial Metallic Material Analysis Office) |

|

Company

name change |

Feb. 28th 2014

Company name changed to Kansai Electric

Heat Co., Ltd. |

Major

customers and industries |

More than 11,000 companies

Each industry (electrical appliances,

mechanical parts, casting and forging, food, packaging, chemicals, medical

equipment, trading and trading companies, environmental hygiene,

shipbuilding, schools / laboratories / automobiles / nuclear power plants,

JAXA), and other related industries |

Industrial

property |

Design registration 66registration

Utility model、Patent(Including Japanese and foreign applications) 64patent |

Main

Bank |

MUFG Bank Tanimachi Branch |

Production

method |

Comprehensive design (research on ceramics, wind

power, and heat-resistant materials), heat-resistant blowers, pneumatic

heat exchangers, electric deodorizers, dry exhaust gas treatment equipment

for CVD equipment, heating wire processing, insulating porcelain,

electronic boards, operation panels, air volume control We manufacture

related equipment, piping sheet metal materials, metal processing, general

assembly, performance inspection, dynamic balance inspection of rotating

equipment, and completion at our own factory in Japan. |

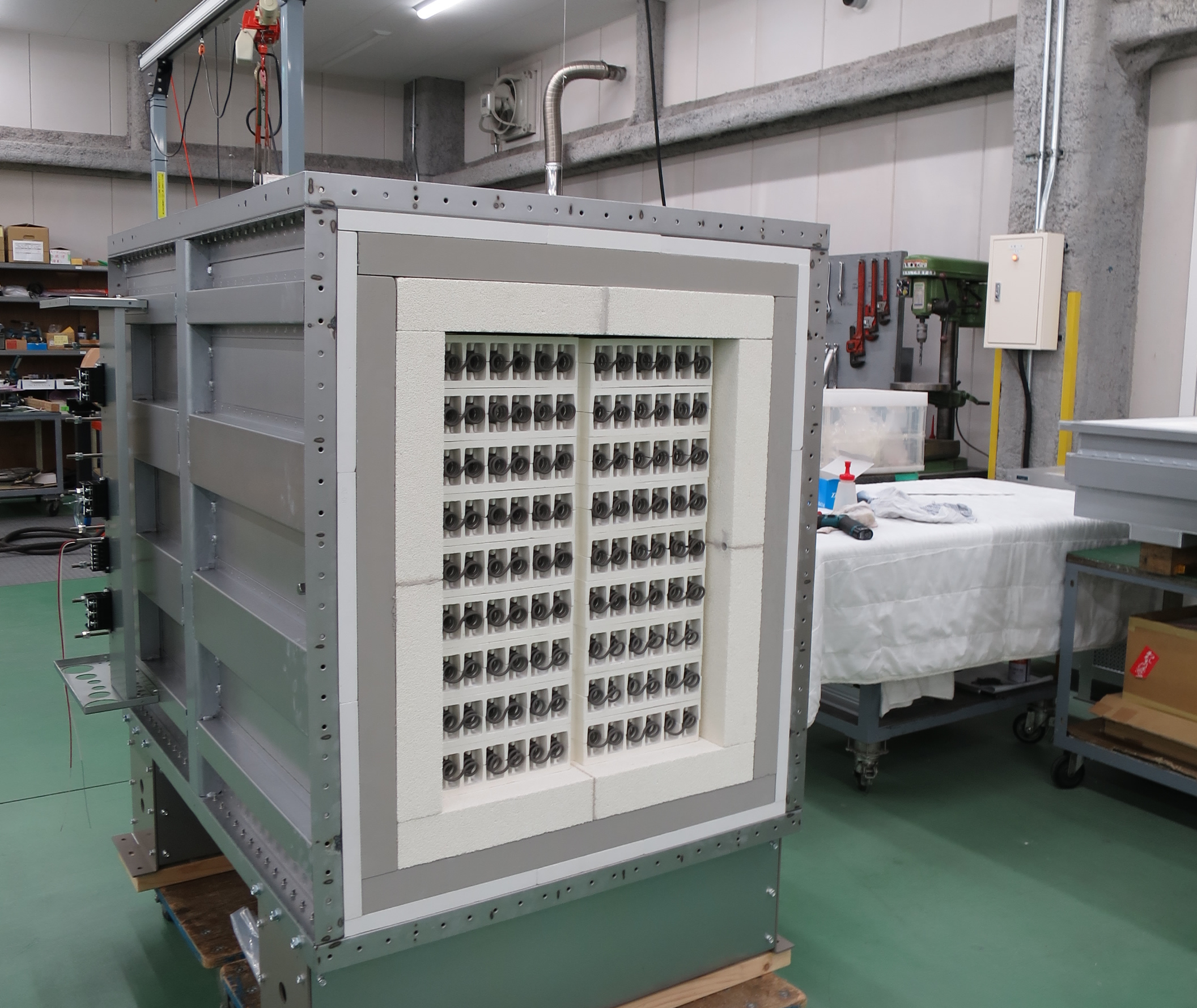

Heater Volume

being produced

|

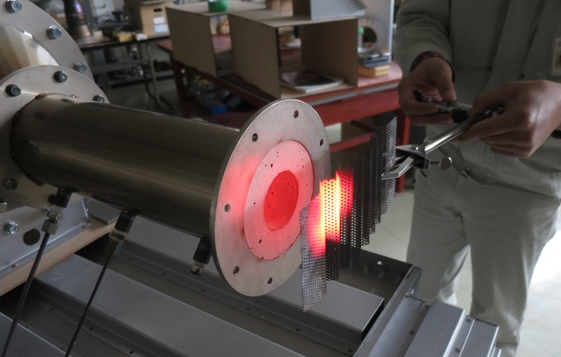

Heater for generating high temperature and high

wind pressure electric hot air.

Standard product with a minimum heater capacity

of 350 W / H from 4,400 kW / H. |

| Annual

factory production capacity |

400,000 kW in

terms of heater capacity Total production for one year, etc. (Sales of

parts such as piping members, filters, blowers, etc.) |

How

to sell |

Direct

sales, mail order, trade sector. |

Industry

classification |

Manufacturing business of applied equipment such as AC motors.

Member of the Excellent Pollution Control and Promotion Council

Registration No. 0211. |

Business

purpose |

1.Development, design, manufacture and sale of

applied equipment such as AC motors and heat generators.

2.All businesses incidental to the

previous issue |

Business

sales item |

| CATALOG No |

Series overview and model of

products handled |

| No.OP |

Air volume control related equipment, piping members, D-type

dampers, automatic dampers, diffusers, flexible hoses, heat

insulating materials for piping, various air filters (Demi filters),

TSK heat exchangers, in-core circulators, TSK heat-resistant

electric blowers, related components |

| No.1 |

Electric hot air

generation block heater, high efficiency honeycomb type, 30kW-405kW.

Maximum capacity4000kW。 |

| No.2 |

Compact and

lightweight hot air generator, multi-dryer HAS-11(1.4kW)〜HAS-43T(5.0kW) |

| No.3 |

Electric hot air

mold dryer、X-3MS(36kW)〜X-5MS(72kW)。Aqueous casting, mold, drying of

core. |

| No.4 |

TSKThe definitive

hot air generator C TYPE SERIES、TSK-18(2kW)〜TSK-200(120kW)。 |

| No.4 aditional |

Heat

exchanger, heat-resistant blower (600 ° C intake),

platinum-catalyzed oxidation deodorizer. In-fire circulator. |

| No.4-1 |

TSKHot air

generator (without operation panel) B type series, large air volume

type, high air pressure type, no blower type. |

| No.4-2 |

TSKHigh wind

pressure hot air generator H type series、TSK-22H4(13.8kPa・3kW)〜TSK-72H9(25.1kPa・20kW)。 |

| No.4-3 |

TSKMedium wind

pressure hot air generator P type series、TSK-24P(3.4kPa・3kW)〜TSK-72P(6.5kPa・20kW)。 |

| No.4-4 |

TSKHigh wind

pressure hot air generator KD series、KD-24H3(12.1kPa・3kW)〜KD-82H5(24.0kPa・30kW)。 |

| No.4-5 |

Part of the

heat exchanger has been remodeled and moved to "Catalog No. 4

Additional Volume". 500 ℃ high temperature heat exchanger HEX-HJ. |

| No.5 |

Super heater for

generating 800 ℃ hot air, SH41 (3kW) to SH71 (20kW), withstand

voltage 490kPa. High temperature hot air unit. |

| No.5-1 |

Dry

exhaust gas treatment equipment for CVD equipment (semiconductor

exhaust gas treatment equipment) Joyclean. |

| No.6 |

Spot heater for

generating 800 ℃ hot air, SH02 (0.7kW) to SH31 (3kW). Withstand

voltage 490kPa, built-in A / B sensor.。 |

| No.6-1 |

800℃Electric heater

for generating hot air SHP40(4.5kW)〜SHP50(10.5kW)。 |

| No.6-2 |

Pen heater, thin

and slim shape、PH12(0.4kW)〜PH22(0.8kW)。 |

| No.7 |

Duct heater for hot

air generation、DH-1L(5kW)〜DH-24(45kW)、Unit heater with pressure

ventilation fan |

| No.8 |

Medium-sized heater

for hot air generation、XS-2A(1.5kW)〜XS-4C(12kW)、SL-3T(4kW)〜SL-6T(7kW)。 |

| No.9 |

Hot

air generator for construction site, KD-43S (7.5kW x 2 circuits,

robust structure, with trolley, hose attached, universal type). |

| No.10 |

Rapid

drainage, aluminum high blow nozzle, 15AL-50AL, 100mm to 2000mm,

abundant variations. |

| No.10-1 |

TSK-PN nozzle

(made of aluminum), cylindrical blow nozzle (made of stainless

steel), pen nozzle (for compressor only). |

| No.10-2 |

Small high

blow nozzle mini, outlet 30 mm (15AL30) -80 mm (20AL80). Compatible

with compressors. |

| No.10-3 |

Low pressure

loss, high performance high blow nozzle SUS, φ50-125, 200 mm to long

ones can be manufactured. |

| No.12 |

Easy-to-use

industrial portable dryer, PD-12 (1.4kW) to PD-12 (3.2kW). Shrink

nozzle. |

In addition, the heaters for generating

ultra-high temperature hot air, Catalog Nos. 13, 14, and 15, have

already been inserted in various related catalogs.

The above maintenance service set. |

|

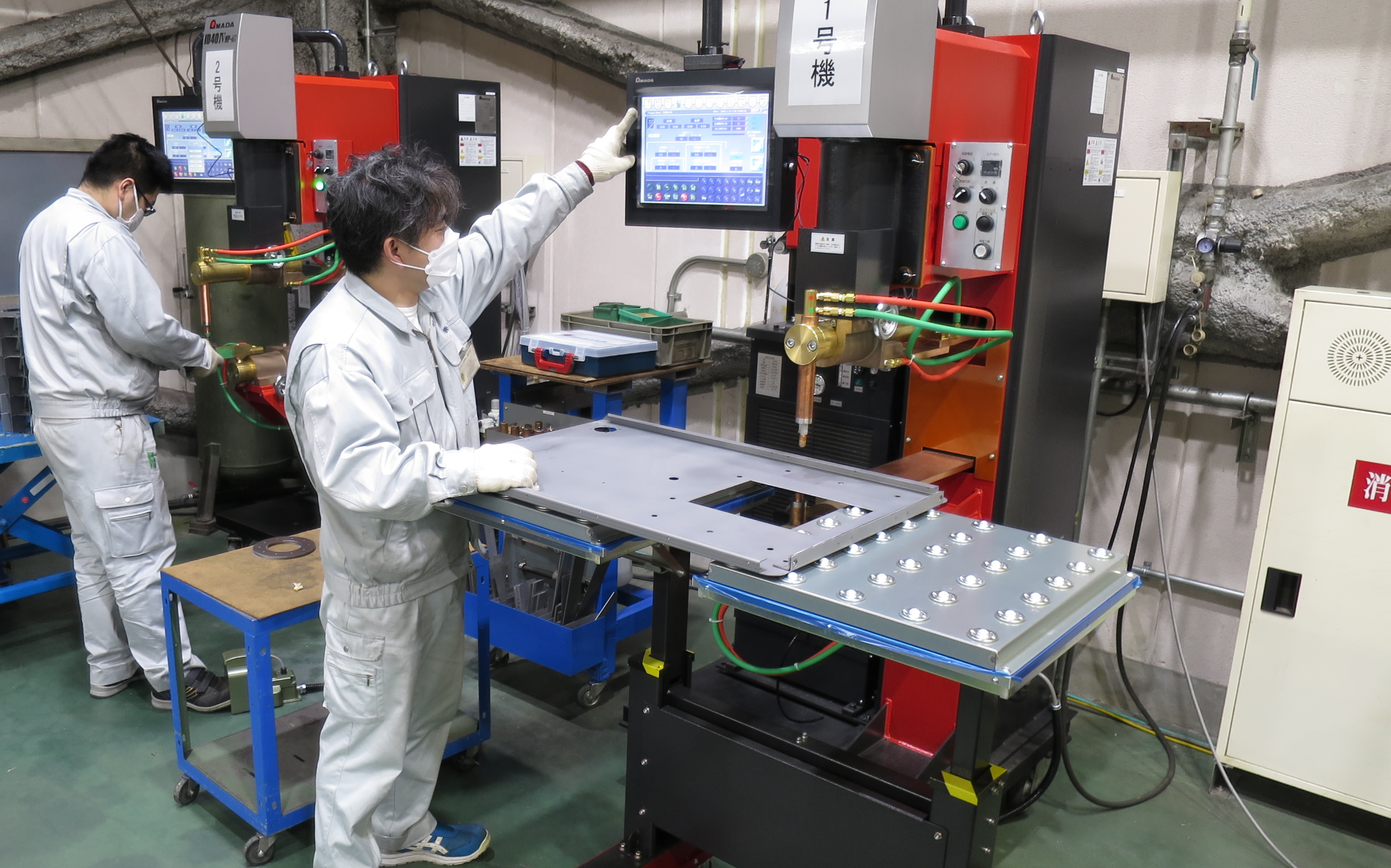

Factory

equipment |

Hybrid drive vendor, process integration,

built-in compact machine, AC servo bending machine, CAD / CAM program

system, turret punch machine, die polishing machine, automatic programming

device, 24-hour automatic heating wire processing machine, automatic

(semi-automatic) welding Machine, M60 hydraulic wrench (MAX60), NC laser

processing machine 2 units, NC turret punch punch 2 units (with

manipulator), NC tapping machine, lathe, upright large drilling machine, 4

bending automatic roll machines 2 units, dynamic balancer 3 units,

shirring , Automatic storage, laser marker, spot punch punch punch punch

punch presser, 130 other major machined sheet metal welding machines /

tools, etc.

4

traveling cranes, withstanding voltage tester, hydraulic pressure tester,

frequency converter, measuring equipment, etc. 95 main assembly machines.

It was

AeroTrak9110 Air particle counter, exhaust gas

treatment experimental equipment, diamond saw machine, hot air drying

furnace, electric furnace, annealing electric furnace, hot air molding

furnace, castable drying furnace, kneading mixer radiation thermometer,

vibration tester, high pressure cleaning equipment, durability 23 units of

power / environmental inspection equipment, various preparations of hot

air generator for sales demonstration.

Power receiving equipment 450KVA. Parking lot

exclusively for the material purchasing section of the head office. |

|